1/2-20 UNF SUPPRESSORS ARE BACK ON!

As many of you know, I stopped manufacturing and selling suppressors for a while after reading the ATF’s interpretation of a silencer and what it considers to be an NFA weapon. It was this article in particular that caused me pause: https://www.atf.gov/firearms/qa/are-paintball-and-airgun-sound-suppressers-considered-nfa-weapons

After looking into it more I came across this case from the US 1st Circuit Court of Appeals: https://caselaw.findlaw.com/us-1st-circuit/1527670.html This case is also referenced in DonnyFL’s disclaimer. Long story short is this: legislators, law enforcement, and the courts all have opinions about the law but ultimately the court’s interpretation is most important and that’s what I’m going with.

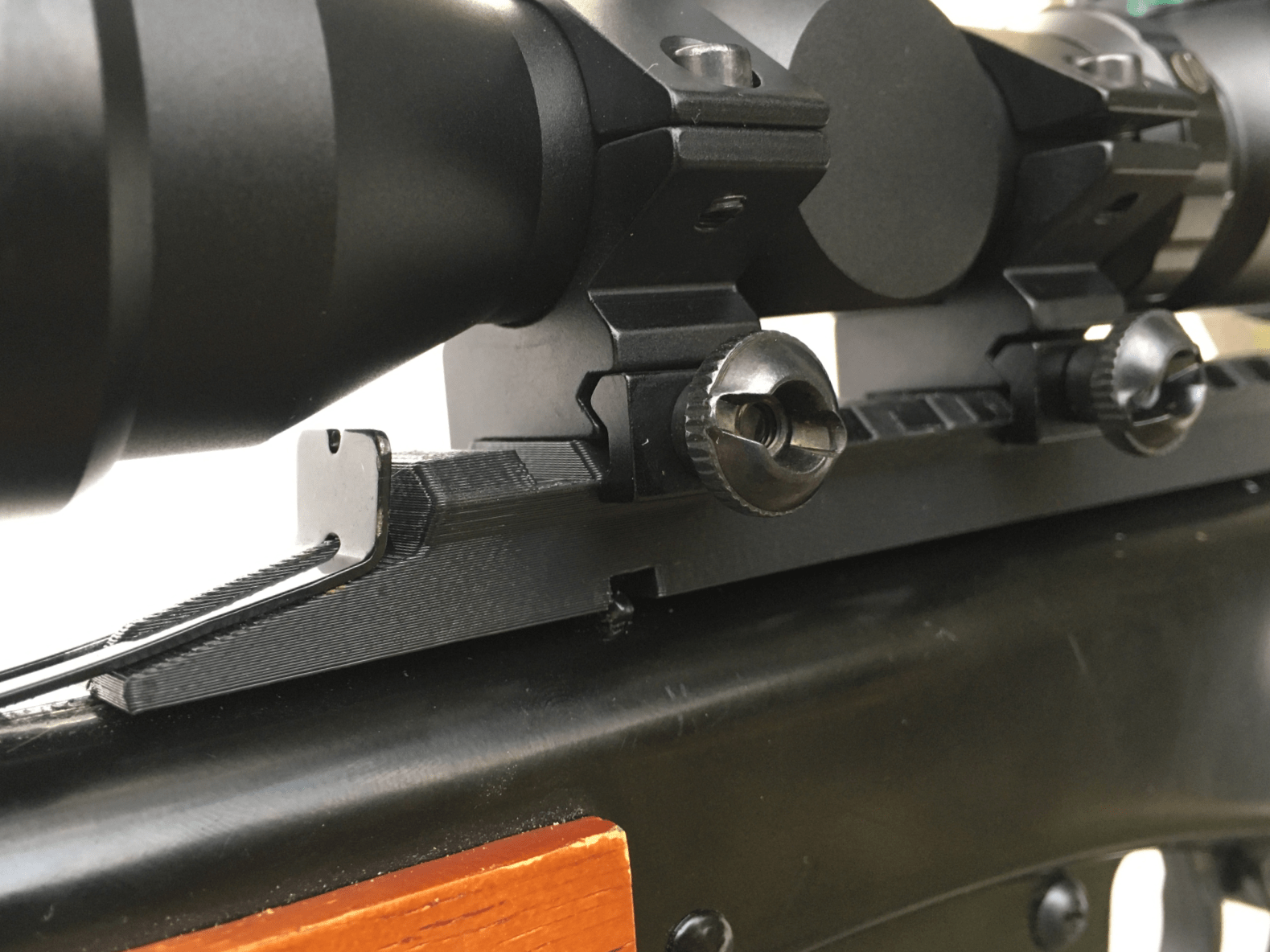

So silencers are back on. I’m sorry for the flip-flopping confusion. For now I’m just going to sell the 1/2-20 UNF and Diana M10 Suppressors. There will be more to come when I find the time.

Thanks for lookin’ y’all!